Products

Galvanzied wire production line

Galvanzied wire production line

- Phone : +8618033712561

- Email : sarah@chinacertifiedsupplier.com

- Wechat : +8618033712561

- Whatsapp : +8618033712561

Product Description

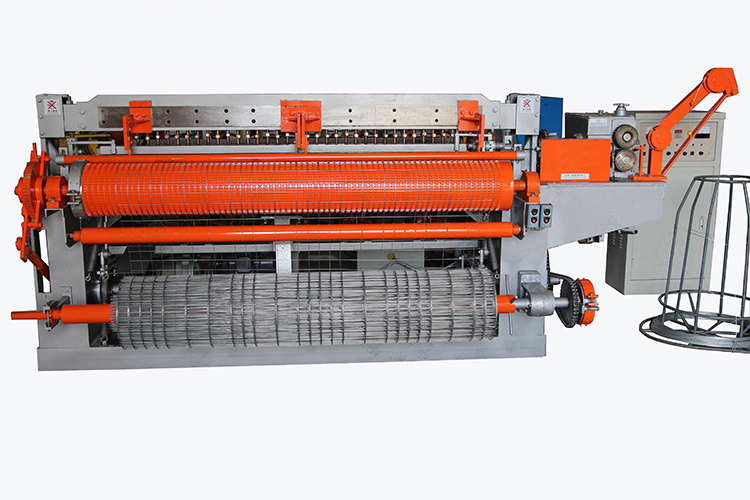

Product Show

Production line design and manufacturing conditions

1,Low carbon steel wire: according to the corresponding low carbon steel wire hot dip galvanized and zinc aluminum alloy standard provisions.

2,wire diameter:1.2~4.0mm

3,Tensile strength: low carbon 450 N/mm2~550 N/mm2

4,Zinc layer thickness: galvanized 30~200 g/square meter.

5,Production speed:D/V40~100

6,Number of wires:40

7,Wire spacing: pre treatment 3mm;Zinc 35mm

8,Production line tooling length: 100m;

9,Heating energy: natural gas

technological process

H wheel winding → gas steel pipe heat treatment annealing → steel wire air cooling → temperature adjustment cleaning → pickling → water cleaning → coating aid plating → drying → hot dip galvanized pot → slanting upward wipe → cooling → water cooling → elephant trunk winding

Production line equipment overview:

1,pay off equipment

The pay off device of i wheel is composed of pay off frame and i wheel. The rotating part of pay off frame is designed with a tensioning and straightening device to control pay off tension.Use I shape wheel outside dimension nan800*600mm, single axis steel wire storage 300~1000 kg, steel wire walk smoothly.

2,Pay off i wheel has vertical and horizontal two forms, customers can choose the vertical structure or horizontal structure according to the actual production needs.

3,Natural gas heat treatment furnace:Multi point independent temperature control, proportional adjustment

| Furnace | Countercurrent muffle frnace type

Countercurrent muffle furnace type

|

| Furnace size | 22000*1800*1500mm |

| Temperature period | Preheat,and heat section 1,2,3,4,5 |

| Control mode | PID Multi Point independent temperature control,proportional adjustment |

| combustion mode | High speed pulse, direct combustion of blast furnace gas

|

| Installation of burner

|

Side mounting

|

| PLC | Siemens S7 300 |

| energy | Natural gas |

Technical parameters:

1) the steel structure of the furnace body adopts the overall frame external dimension: L22000*W1300*H1500 (mm)